MATERIALS DEVELOPMENT AND MANUFACTURING TECHNOLOGY PLATFORM

ENP Constantine

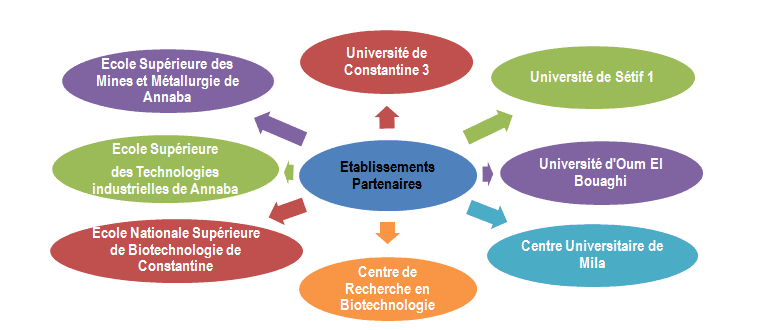

Created by interministerial order of August 31, 2019 setting a joint research service within the Ecole Nationale Polytechnique de Constantine – Malek Bennabi, the technology platform with eight (08) partner institutions is composed of three (03) sections: “Development” section, “Manufacturing” section and “Analysis, Evaluation and Maintenance” section.

Partner Institutions

The Three (03) Sections of the Technological Platform

Section of elaboration of materials is dedicated

- to develop high-performance metallic materials,

- to develop high-performance ceramic materials,

- to develop high-performance composite materials,

Prototype manufacturing section is dedicated

- to manufacture metal prototypes,

- to manufacture ceramic prototypes,

- to manufacture composite prototypes,

Analysis, Evaluation and Maintenance section is dedicated

- to evaluate and control the materials used in the manufacture of prototypes,

- to make tests on the manufactured prototypes,

- to ensure the maintenance and repair of the equipment.

Equipment of the Technological Platform

Elaboration section

- induction furnace 1800°C

- heat treatment furnaces 1400° C and 1500°C

- set of vacuum heat treatment furnaces (1500° C furnace and 1400° C sintering furnace)

- crusher and screening machine

- extruder for ceramic paste

- ultra fast sintering system (spark plasma sintering)

- high temperature sintering furnace with debinding furnace

Manufacturing Section

- sinker EDM machining center

- 5-axis machining center (ultrasonic assisted as an option)

- 3-axis CNC machining center (turning and milling)

- 200 ton motorized hydraulic press

- water jet cutting machine

- laser welding and curing

- plasma coating machine

- Nitrogen generator

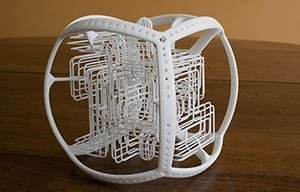

- 3D printer for ceramics

- 3D metal printer with sintering and debinding furnace

- 3D resin printer 3D scanner with structured light for reverse engineering and quality control

- 3D printer for thermoplastic with scanner

- scientific glass blowing workshop

- potentiostat- Galvanostat with impedance meter

- Atomic Force Microscope (AFM)

Analysis, Evaluation and Maintenance Section

- 3D Profilometer -Rugosimeter

- Radiofrequency Glow Discharge Spectrometer GDOES

- X-ray diffractometer for the evaluation of manufacturing materials

- DSC/ATD/ATG 1600° C

- bi-axial fatigue machine

- Universal mechanical testing machine 200 kN

- X-ray fluorescence

- FTIR-ATR infrared spectrometer

- microdurometer

- Transmission Electron Microscope (TEM/FEG)

- differential dilatometer (TMA) 1600° C

- rheometer

- BET and density meter

- MEB/FEG to evaluate and control materials used in manufacturing

- XPS

- electronic preparation and repair workshop

- mechanical preparation and repair workshop

.

Contact us

- Ville Universitaire Ali Mendjeli - BP 75A RP Ali Mendjeli -.<br>

Constantine